A Breakthrough in 4D Printing of Multifunctional Composites

In an age of rapid advancements in adaptive and intelligent technologies, materials that can change shape independently are no longer science fiction—they are becoming a reality. A recent study from the University of Colorado Denver, published in Nature Communications [1], introduces a groundbreaking 4D printing technique that enables the design and creation of multifunctional composites capable of complex shape changes beyond traditional axial or folding deformations.

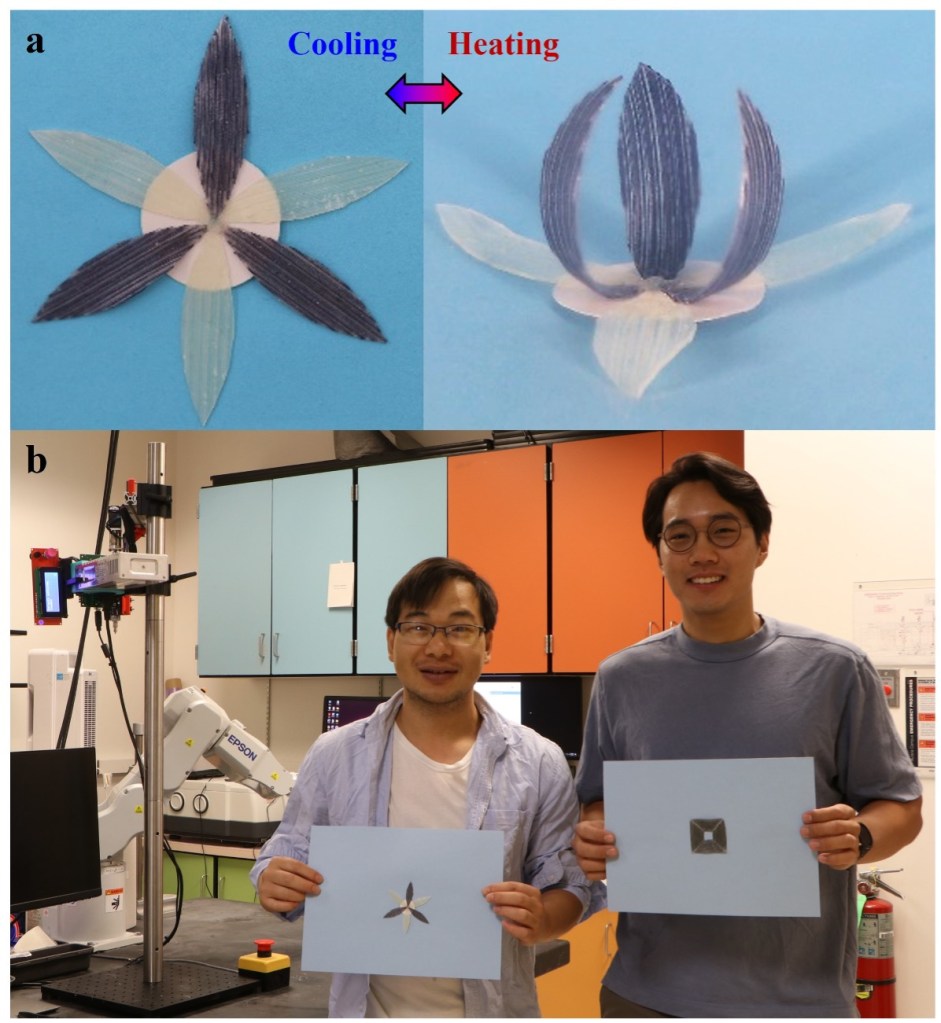

The secret behind this breakthrough is the integration of continuous fibers into a liquid crystal elastomer (LCE) matrix – a material that changes shape when heated. These fibers not only enhance the speed and force of actuation but can also be strategically arranged to collaborate with the material’s actuation properties. The research team has created structures that can twist, helix, warp, or curl by designing specific fiber orientations and patterns. Once cooled, these materials return to their original “remembered” shapes in predictable ways (Figure 1a).

Figure 1: (a) A 4D-printed LCE composite flower demonstrating reversible shape changes through temperature control. (b) Dr. Huan Jiang (left) and Christopher Chung (right).

Imagine a robotic arm that curls its fingers to grasp an object, a wearable device that adapts for a perfect fit, or a sensor that moves autonomously. These are just a few of the possibilities unlocked by this new approach. The advanced shape-changing capabilities could lead to groundbreaking designs for future soft robotics, adaptable metamaterials, and morphing space structures.

Even more exciting is the versatility of this method. A variety of resins and functional fibers can be incorporated into the LCE system. For example, adding conductive fibers allows the material to be remotely activated by an electric signal, which opens new possibilities for intelligent devices in industries such as aerospace and wearable electronics.

Beyond actuation, the synergy between continuous fibers and the LCE matrix enhances the material’s mechanical properties, such as energy absorption and protection. This makes it ideal for applications requiring both flexibility and durability, including healthcare and biomedical devices.

The study is led by Professors Kai Yu and Martin L. Dunn from the Department of Mechanical Engineering at CU Denver. The first author is postdoctoral researcher Dr. Huan Jiang, with PhD student Christopher Chung as the second author (Figure 1b).

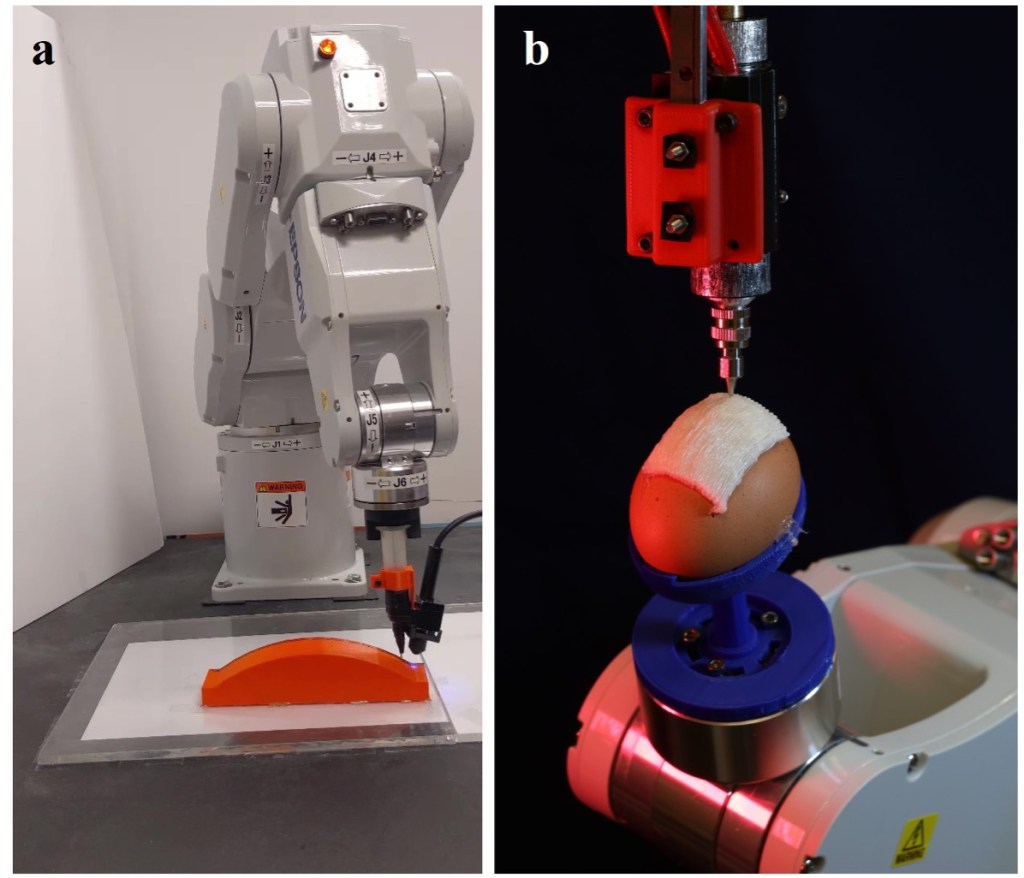

Figure 2: (a) Robotic arm driven composite 3D printing on curved surfaces. (b) Printing of protective LCEs on an egg surface.

This 4D printing innovation builds upon the team’s extensive research into advanced 3D printing techniques for continuous fiber composites [2-6]. For several years, they have been developing innovative printing techniques that merge robotic precision with cutting-edge materials (Figure 2a) [4]. In addition to shape-changing materials, the group has expanded to include a wide range of functional resins, from recyclable [6] to energy-absorbing materials. In one striking demonstration (Figure 2b), they printed energy-absorbing LCEs directly onto a raw egg, which created a protective shield that can prevent the dropped egg from breaking. The multifaceted approach reflects the team’s commitment to pushing the boundaries of 3D and 4D printing and providing creative, adaptable solutions to complex engineering challenges.

The research of the team is funded by the National Science Foundation (CAREER CMMI-2046611) and the Air Force Office of Scientific Research (FA-20-1-0306).

References

1. Jiang, H., et al., 4D printing of liquid crystal elastomer composites with continuous fiber reinforcement. Nature Communications, 2024. 15(1): p. 8491.

2. He, X., et al., 3D printing of continuous fiber-reinforced thermoset composites. Additive Manufacturing, 2021. 40: p. 101921.

3. Abdullah, A.M., et al., Direct-write 3D printing of UV-curable composites with continuous carbon fiber. Journal of Composite Materials, 2023. 57(4): p. 851-863.

4. Abdullah, A.M., M.L. Dunn, and K. Yu, Robotic 3D Printing of Continuous Fiber Reinforced Thermoset Composites. Advanced Materials Technologies: p. 2400839.

5. Ding, Y., et al., Embedded 3D printing of UV-curable thermosetting composites with continuous fiber. Materials Horizons, 2024.

6. Jiang, H., et al., 3D Printing of Continuous Fiber Composites Using Two-stage UV Curable Resin. Materials Horizons, 2023.

Categories

Diversity, Faculty, Mechanical Engineering, Research Opportunities, Students

Discover more from College of Engineering, Design and Computing News

Subscribe to get the latest posts sent to your email.

CU Denver Engineering, Design and Computing View All

At the CU Denver College of Engineering, Design and Computing, we focus on providing our students with a comprehensive engineering education at the undergraduate, graduate and professional level. Faculty conduct research that spans our five disciplines of civil, electrical and mechanical engineering, bioengineering, and computer science and engineering. The college collaborates with industry from around the state; our laboratories and research opportunities give students the hands-on experience they need to excel in the professional world.

One thought on “A Breakthrough in 4D Printing of Multifunctional Composites” Leave a comment ›